The End of Heavy Wiring: Why Waterproof, Modular Lithium Batteries Are Winning the Kayak Game

Stop drilling holes in your kayak just to run a power cable.

For years, a typical kayak trolling motor setup required three separate components: a battery, a battery box, and exposed wiring running across the deck. Add in a fuse block, terminal clamps, and constant corrosion checks—and what should be a lightweight craft starts to resemble a small-boat electrical project.

Your propulsion system is only as good as the energy driving it. And in kayak applications, heavy, exposed, and poorly sealed battery systems limit performance more than most paddlers realize.

The shift toward waterproof, modular lithium trolling motor batteries is not a trend—it is a correction.

Weight Matters: The “Power-to-Weight” Ratio Explained

A kayak is not a bass boat. It does not tolerate excess mass.

A traditional 24V marine battery setup using lead-acid or AGM cells often adds 20–30 lbs before wiring and housing are even considered. That weight sits high, shifts balance, and forces the hull to carry its own power source inefficiently.

Lithium systems change the equation by improving the power-to-weight ratio, not just raw capacity.

Saving 20 lbs on a battery isn’t just about weight—it’s about what that weight allows you to do instead.

It can mean carrying an extra cooler, more tackle, or simply paddling faster and with less fatigue when pushing against wind or current.

On a kayak, lighter power translates directly into a better on-water experience.

Why 1 lb on a Kayak Equals 5 lbs on a Boat

Small displacement hulls are extremely sensitive to weight distribution. Adding 1 lb to a kayak affects trim, acceleration, and maneuverability far more dramatically than the same addition on a fiberglass boat.

A heavy battery:

-

Reduces acceleration efficiency

-

Increases drag and draft

-

Slows recovery in current

-

Makes wind correction more demanding

A lightweight kayak battery preserves hull performance instead of compromising it.

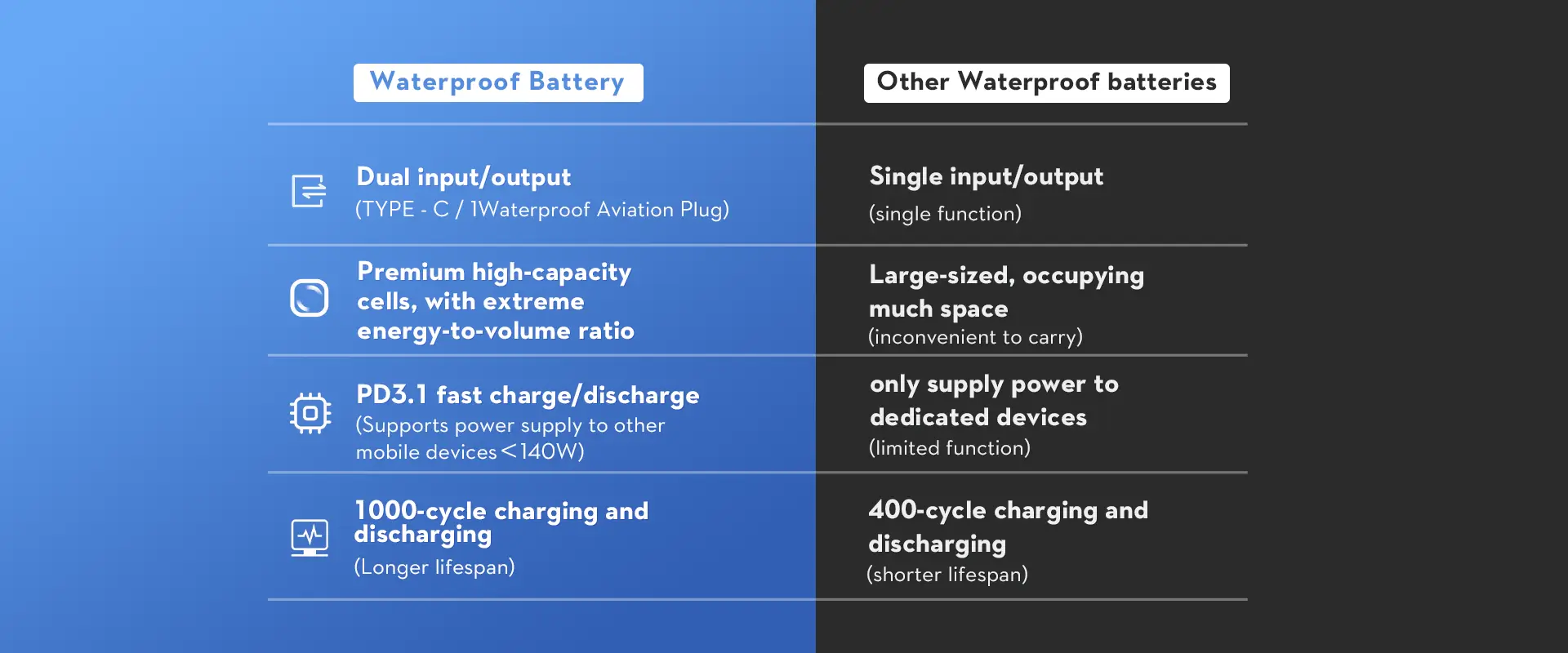

Lithium vs. Lead-Acid: A Real-World Comparison

On paper, both battery types can deliver voltage. In real-world kayak use, the system design matters as much as the chemistry.

Lead-acid / AGM systems are heavy, suffer from voltage sag under load, and offer limited usable capacity.

Generic lithium batteries improve energy density and cycle life—but they still rely on external wiring, exposed terminals, and separate battery boxes. That means corrosion risks, waterproofing compromises, and DIY electrical work remain.

The difference with the Edge K4 Modular Battery System is integration.

By combining a built-in BMS, sealed marine-grade housing, and a proprietary connection interface, the K4 system eliminates the intermediate components entirely. There are no loose cables, no external terminal posts, and no reliance on third-party battery boxes to keep water out.

In other words, while lithium chemistry improves performance, native integration is what removes failure points.

Stop Buying Battery Boxes: Why Fully Sealed Modules Are the Future

Searching for a “kayak battery box setup” often leads to plastic enclosures with rubber gaskets and cable pass-through holes.

The weak point is not the lid—it’s the wiring.

Every external cable, gland, or terminal opening becomes a potential ingress point, especially in saltwater environments.

A truly waterproof kayak battery should not require a box at all. It should be sealed from the factory as a single structural unit.

IP68 Standards and Saltwater Protection

Ingress Protection (IP) ratings define resistance to dust and water. An IP68-rated system can withstand temporary submersion without internal water intrusion.

This matters during:

-

Heavy spray

-

Accidental submersion

-

Capsize recovery

-

Saltwater exposure

The K4 Waterproof Power Module is engineered as a fully sealed unit, reducing corrosion risk and eliminating exposed electrical contacts.

Eliminating Corroded Terminals

Traditional battery setups rely on exposed posts, ring terminals, and manual tightening—all of which degrade rapidly in marine conditions.

By removing open terminals entirely, integrated systems reduce:

-

Maintenance cycles

-

Contact resistance

-

Electrical inefficiency

-

Long-term reliability risks

For saltwater kayak anglers, this is not a convenience upgrade—it is a durability requirement.

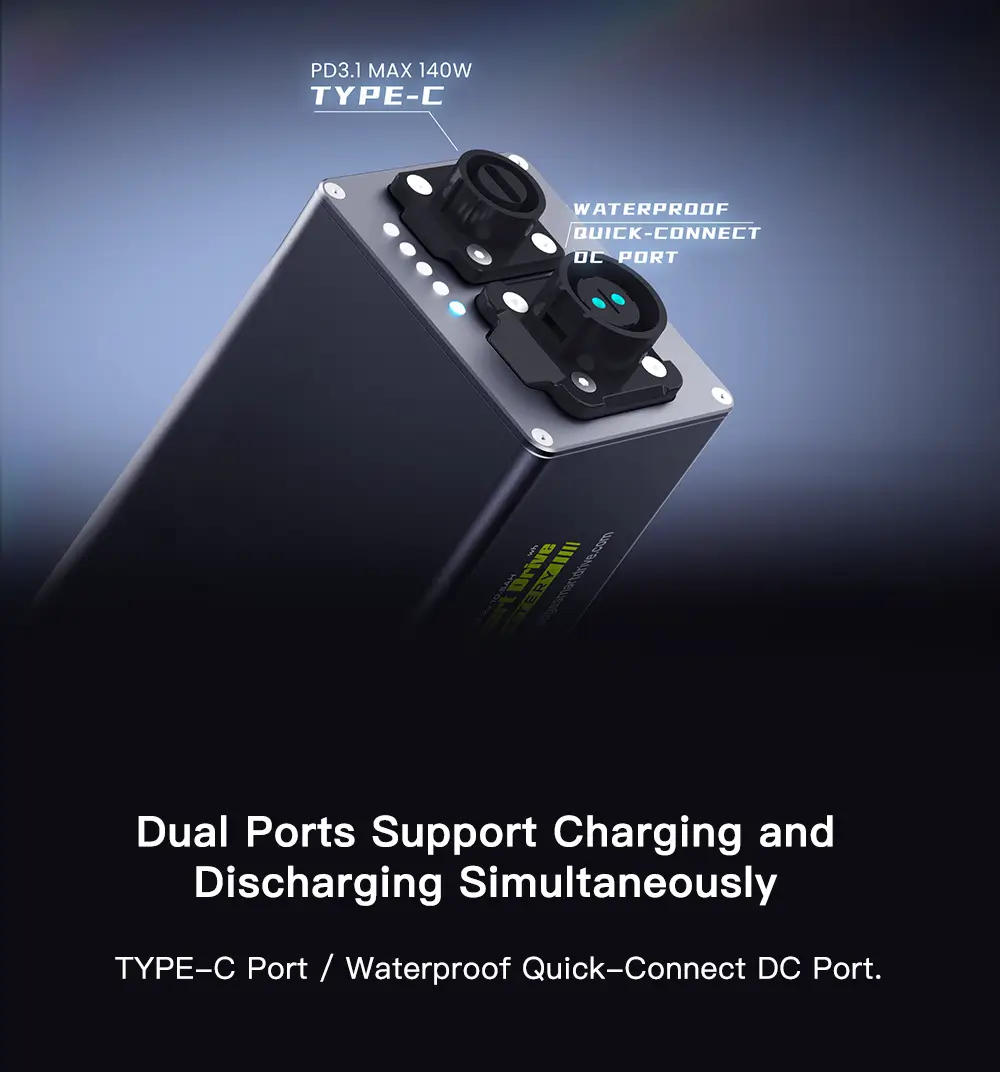

Plug-and-Play Efficiency: The Edge Smart Drive Battery Ecosystem

Most trolling motors still expect users to build their own electrical system: sourcing batteries, fuses, wiring, and waterproof enclosures.

The Edge K4 Modular Battery System takes a different approach. It is designed as part of the propulsion system itself.

No Wiring, No Drilling, No Stress

Instead of exposed cables, the K4 battery uses a self-aligning slide-in interface that clicks into place in under 3 seconds.

There is no crimping, no routing wires across the deck, and no drilling holes for power cables. Compared to a traditional setup that can take 30 minutes or more, the difference is immediately obvious.

The Edge K4 battery is the housing. It is fully waterproof (IP68) right out of the box. No plastic containers, no straps, and zero water ingress risk.

The connection is purpose-built for the K4 propulsion unit, ensuring electrical efficiency, sealed contact, and repeatable installation every time.

Double Your Range with Swappable Modules

Recharging takes time. Swapping does not.

A modular system allows paddlers to carry a second sealed power module and swap it in seconds—instantly extending range without downtime or reconfiguration.

This is particularly valuable for long fishing days or remote water where charging access is limited.

How to Maximize Your Battery Life on the Water

Lithium systems require less maintenance than lead-acid batteries, but good practices still matter.

Storage & Maintenance Tips

To extend service life:

-

Avoid deep over-discharge

-

Store partially charged during long-term storage

-

Keep sealed interfaces capped when not in use

-

Use the recommended charging system

With proper care, lithium modules can deliver several times the usable lifespan of traditional marine batteries.

For all-day expeditions, serious anglers often carry two modules to ensure uninterrupted power.

If you're organizing gear for longer trips, consider a Gear Transport Bundle—which includes a dry bag designed for your phone, keys, and clothing. The battery itself does not require additional waterproof storage.

Conclusion: Integrated Power Is the Future of Kayak Propulsion

Heavy wiring, exposed terminals, and improvised battery boxes belong to an older generation of marine setups.

Modern kayak propulsion demands integrated, sealed, and weight-optimized power systems designed specifically for small craft.

The Edge K4 Modular Battery System reflects this shift—eliminating wiring complexity while improving reliability and on-water performance.

The future of kayak power isn’t more cables.

It’s integrated energy.

K4

K4 K5

K5